Original IoT Think Tank

Please indicate the source and source for reprinting

Introduction

Following cars and smart phones, the dilemma of "core shortage" in the home appliance industry has gradually emerged in the public's field of vision.

The "core shortage" storm has swept the world, and it is destined to "no survivors."

In recent months, emergencies such as factory fires, power outages, cold waves, and the intensification of the new crown epidemic have added a handful of firewood to the chip manufacturing industry, which is already in "distressed water". For a while, when will the chip shortage be resolved? The most concerned issues of the upstream and downstream of the industrial chain of all walks of life.

A recent Goldman Sachs research report shows that as many as 169 industries around the world have been hit by the shortage of chips to a certain extent, covering many fields from steel products, concrete production to air-conditioning manufacturing, beer production, and even The soap manufacturing industry has also been affected. After cars and smart phones, the dilemma of "core shortage" in the home appliance industry has gradually emerged in the public's field of vision.

The global home appliance industry is in a chip crisis

Recently, Ningbo Evening News reported that Fang Shuguang, chairman of Ningbo Qixi Intelligent Technology Co., Ltd., said in his circle of friends that "everything is ready, only owed chips." The company is a professional manufacturer of water purification equipment and core supporting products integrating R&D, manufacturing, and sales. Its circuit boards will directly use control chips, and the main source is domestic chips. At present, the core shortage they have encountered has been very serious. , Which has a great impact on the company's production.

Song Xiaochuang, the relevant person in charge of Yueli Group Co., Ltd., a leading home appliance company specializing in the production of beauty and beauty generators and personal care appliances, also introduced to a reporter from the Ningbo Evening News that although the company does not directly purchase chips, it needs to be used in products such as high-speed hair dryers. Although these products account for less than 10% of motors with integrated chips, the "core shortage" has led to a nearly 15% increase in the production cost of the whole machine.

Gan Jianguo, general manager of Philips Air Conditioning (China) Operations Headquarters, also told China Business News that the chips on the air conditioner computer board have been in short supply since November last year, and the chip delivery cycle has been extended. Currently, it is necessary to come 180 days or even 360 days in advance. Stocking up, while in the past it only needed to stock up to 45-60 days in advance. Except for American and Japanese companies, chip suppliers currently account for 50% of domestic supply.

Coincidentally, not only China, but the global home appliance industry is in the shadow of a chip shortage. A small TV manufacturer in Seoul said that it will be difficult to obtain key components unless it pays a higher price; Han Jong-hee, vice president of Samsung Electronics in charge of the TV department Said that more than half of the world's TV manufacturers are facing a chip shortage problem, so that many companies will not be able to make TVs at all. Home appliance manufacturer LG Electronics said that the chip shortage has not affected the company's overall production at present, but it also acknowledges that it does pose a risk.

Related research reports pointed out that the current white appliances field, especially intelligent functional appliances, is greatly affected by the tightness of frequency conversion smart chips. The upstream CPU, memory, flash memory and other chips of the color TV industry chain are also in a state of shortage. Small appliances, kitchen appliances, upstream artificial intelligence Voice control chips, sensor chips and IoT chips are all out of stock to varying degrees.

Double pressure on both sides of supply and demand

Freezing three feet is not a day’s cold, and the "chip shortage" in the home appliance industry is not a short-term result. In the global chip storm, the home appliance industry not only bears the huge competitive pressure on the chip supply side, but also needs to face the consumer market. Increasing buying demand.

On the supply side, since the chips used in the home appliance industry are mostly low-margin processors with simple functions, industry insiders have analyzed that in the current shortage of chip production capacity, chip manufacturers give priority to allocating production capacity to high-margin products, and home appliance chips are ranked In the end, this resulted in a situation in which demand was in short supply.

On the demand side, with the rapid popularization of smart homes, traditional home appliances have ushered in a large-scale intelligent upgrade. Taking color TV as an example, with the development of ultra-high-definition, AI and other technologies, color TV has become a new interactive terminal for smart homes. With the blessing of intelligence and linkage scenarios, the color TV market has gradually shown a "volume derating and increasing" scene. Similarly, traditional home appliances such as refrigerators, air conditioners, and washing machines have also been implemented with the advancement of whole-house intelligence, which indirectly stimulates consumer demand. According to a report released by Verified Market Research, the global smart home market is expected to reach USD 207.88 billion by 2027. With the rapid development of the industry, the intelligence of home appliances is increasing day by day, and the complexity of the chip functions and the number of chips behind it have been improved to varying degrees.

The most intuitive manifestation of the shortage of chips is the price increase. Under the hot environment of short supply, domestic micro-control chip manufacturers Smart Microelectronics and Rockchip have announced that they will adjust the prices of chip products to varying degrees from April 1. rise. At the same time, manufacturers such as Renajie Semiconductors, Minsil Microelectronics, and Huiman Microelectronics have also issued notices of product price increases. For home appliance manufacturers, problems such as the sharp drop in chip delivery, the increase in production costs, and the lag in the development of new products have come one after another. In order to balance costs, price increases are really helpless.

Source: Network

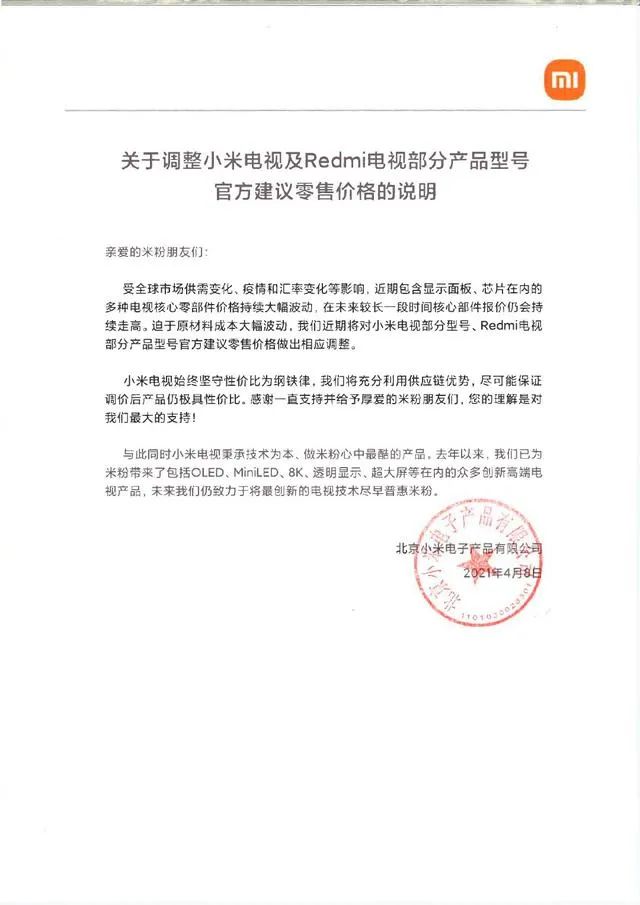

Since the beginning of the year, many domestic appliance giants, including TCL, Hisense, Midea, and Oaks, have successively issued notices of price increases. Xiaomi announced in early April that due to the fluctuations in the prices of components such as panels and chips, the quotations continued to rise and it would adjust TV prices.